From Innovation to Industry

Explore how Carbience's proven CO₂ conversion technologies are ready for real-world deployment — and where they go next.

Field-Ready Demonstrators

Explore how our CO₂ conversion technologies have been tested, optimized, and engineered for deployment.

-

• 95%+ CO₂ conversion at ambient conditions

• 0.5L/min gas flow tested for 24 hrs continuous run

• Image or schematic illustration

-

• Operates at 60–70°C, ≤3 bar

• Achieved 95% yield with epoxides

• Designed for scale-up to 10L batch reactor

-

• Containerized RCC module mock-up

• Plug-and-play for emission point installations

• Shown in industrial scale rendering or CAD

Products from CO₂ Conversion

Our technology platforms have successfully synthesized high-value cyclic carbonates directly from CO₂ — verified under lab-scale and pilot conditions.

-

Ethylene Carbonate (EC)

• Key solvent for lithium-ion batteries

• Synthesized via RCC at ambient pressure

• 98% purity confirmed via GC-MS

-

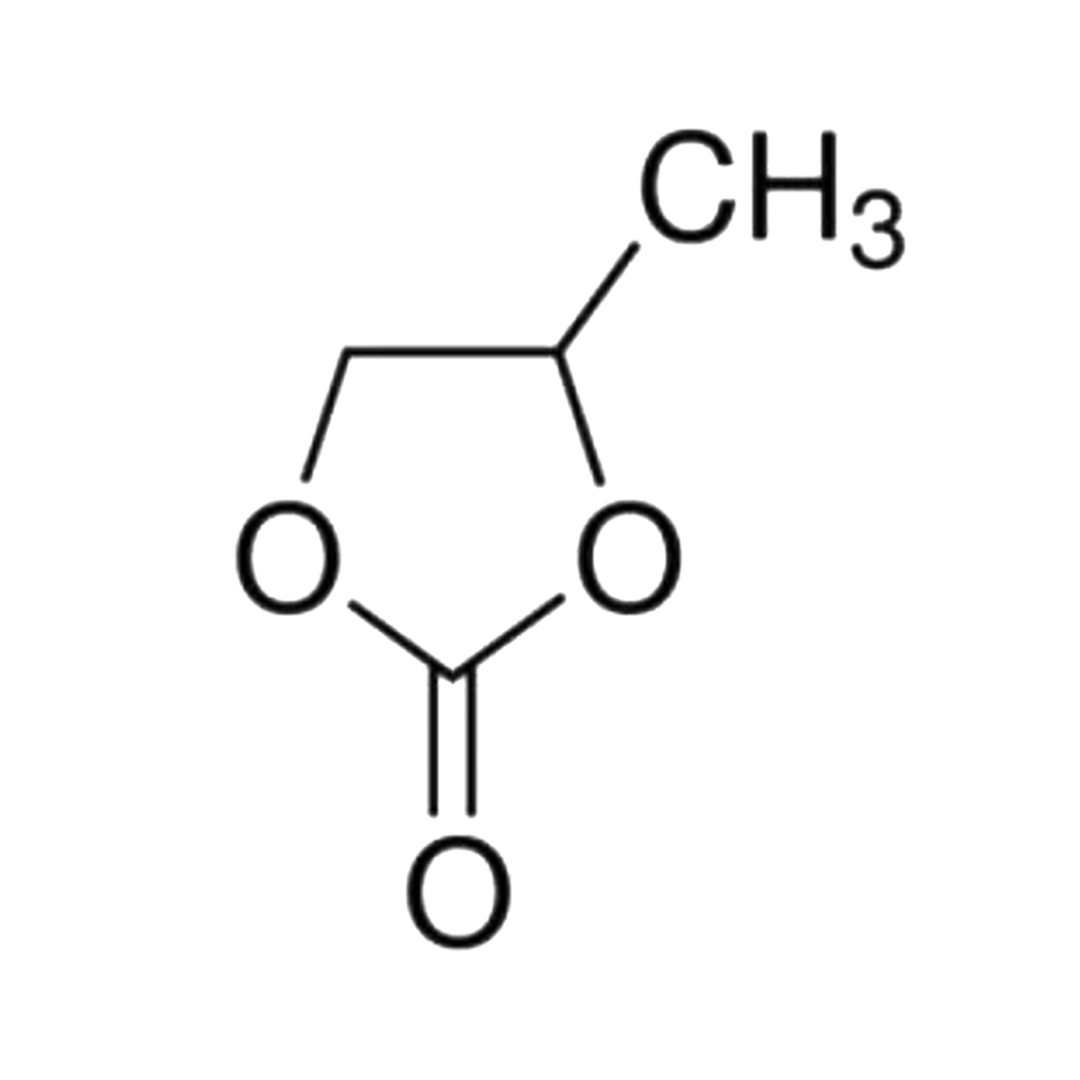

Propylene Carbonate (PC)

• Used in electronics, coatings, electrolytes

• Produced using LEC with propylene oxide

• 95%+ yield, <1% residuals

-

Epoxide-Based Cyclic Carbonates

• Epichlorohydrin, Styrene oxide, GMA

• Demonstrated versatility across epoxides

• Platform compatible with >6 epoxide types

From CO₂ to Carbonates.

From Lab to Industry.

Carbience’s platforms have synthesized proven cyclic carbonates and demonstrated their deployment potential — ready for integration across industries and value chains.